Wataru Shimamoto, the masterful Japanese shoemaker behind the brand Orma Shoemaker, is an inspiring figure in the world of bespoke footwear. With a background at Il Micio in Italy, he’s now back in Japan since some years carving out a niche for himself in the competitive landscape of shoemaking, culminating in his victory at the World Championships of Shoemaking in 2022.

In a small village called Nishikamakura, up in the mountains between Kamakura and Enoshima, one find the showroom and workshop of Orma Shoemaker. It takes about an hour and a half to get here from Tokyo, and if one go by public transportation the last part one take the Shonan Monorail where the trains hang in their roofs and float above the roads, houses and tree tops on it’s way through the countryside.

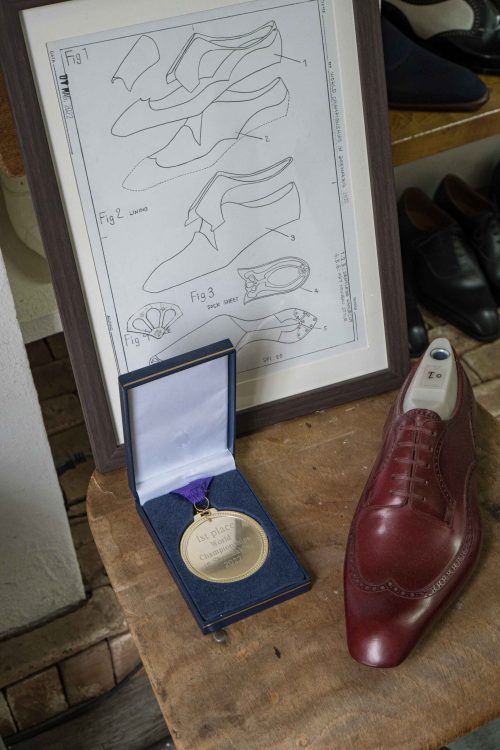

Wataru Shimamoto, the man behind Orma (which means “footprint” in Italian), lives nearby. The Orma space here is a very elongated room where the showroom parts seamlessly transition into a workshop in the back. As often is the case when it’s all mixed in one room, there’s a thin layer of wood and leather dust over the sample shoes, but that doesn’t take away from the overwhelming shoe creativity that is showcased here. Shoe after shoe with interesting and unique design choices.

– I really love shoes, it’s my passion. I love both the creative process and the craftsmanship, Wataru says.

Wataru found his way in to the shoe world in his early 20’s, where he spent three years working at a local shoe repair shop. During this time, he diligently taught himself the fundamentals of shoemaking. His commitment to self-education and discipline was evident already here, and foreshadowed the rigorous path he would later pursue.

At the age of 25, Wataru’s quest for greater knowledge and refinement in shoemaking led him to Italy, and Florence. He spent the next decade honing his craft at Il Micio, a renowned shoemaking workshop run by the legendary shoemaker and fellow countryman Hidetaka Fukaya (read a report about Il Micio in this article from 2016). At Il Micio, Wataru specialised in bottom-making, the part that includes welting, sole stitching and finishing. He gained a reputation as a really classy maker with not least a very high level on his finishing. During the time in Italy, he also continued to train on other parts than bottom making in evenings and weekends.

In July 2020, after 10 years in Italy, Wataru Shimamoto moved back to Japan, bringing with him the extensive skills and nuanced knowledge he had acquired in Italy. He founded Orma Shoemaker, where he could fully realise his vision for shoemaking.

– Now I do every stage of the shoemaking process, lastmaking, upper making as well as bottoming.

One of the most challenging aspects for Wataru was lastmaking. Although he had studied this independently, consulting shoemaking books to perfect his technique, he acknowledged it as the most difficult skill to master.

– It’s a very different to bottom making and upper making, when you have to understand the customer and his feet on a different level, says Wataru.

This is where he still develops the most, and learns the best way to solve various challenges and issues.

Orma’s shoes shows some signs of Wataru Shimamoto’s training at Il Micio and in Italy, with often long elongated toe shapes, and a subtle peak positioned further back than those found at Hidetaka Fukaya. Wataru then adds more Japanese influences both when it comes to patterns and materials chosen. One notable choice is shironameshi, a traditional white Japanese leather known for its natural grain and exceptional durability. Tanned solely with water, salt, and rapeseed oil, shironameshi is highly valued for its unique properties and special look, even if it’s very expensive due to the time consuming production.

The soles have a natural, clean finish, often in contrast to the more special uppers. Stamp of course inspired by John Lobb Ltd’s classic one. You can also see the slightly oval shape the Orma shoes often have in the back.

One of his most popular models is a balmoral oxford, this he also offers as MTO on standard lasts, which starts at €2,700 (450,000 yen, he do max ten MTO pairs per year). Bespoke options begin at €3,600 (600,000 JPY). Each shoe takes approximately 40 hours to complete, excluding the lastmaking and production of fitting shoes. He works six days a week.

Wataru Shimamoto’s work achieved global recognition in 2022 when he won the World Championships of Shoemaking, following up his fourth place in the 2018 contest. The shoe that gave him the win was an exceptional piece, and creating this pushed his craft to a new level. The victory boosted his reputation, especially among international clients, something basically all who finish high in the world championships testify to.

About 1,500 nails in each shoe. Still took more time to make the single shoe for the world champs than this pair.

This newfound interest coincided with Japan’s reopening after pandemic restrictions, giving him the opportunity to expand his clientele.

– I hope to continue expanding my reach and also maybe do more international trunk shows in the future, Wataru says.

Craftsmanship at this level certainly should be of global interest.